Dry Mounting

1. Applications

We offer a comprehensive dry mounting service and stress that this is a permanent process, applied to works that need to be made flat for display.

Dry mounting is not reversible and we will always ask you to be aware of the implications for your artwork.

Once mounted flat, there are a range of framing options available that otherwise might not be successful, such as: box framing to the edge of the work, tray framing without glass, float mounting of large scale light-weight papers, or displaying as a floating panel without any frame at all.

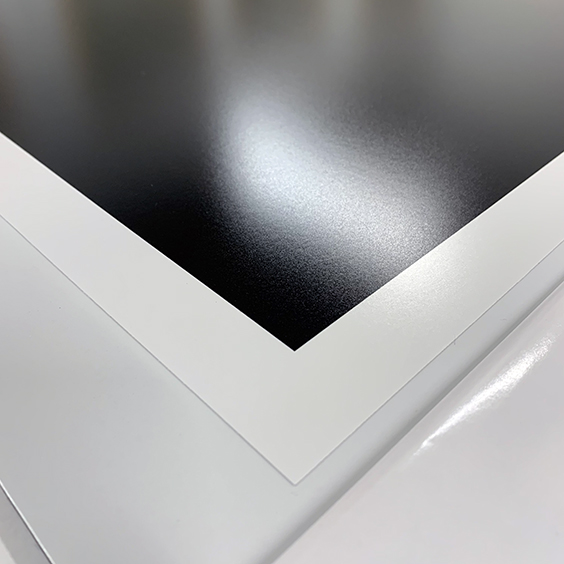

Photographic prints particularly benefit from dry mounting. We offer cold roller pressing to di-bond for modern chromogenic prints with unparalled flatness.

Dry mounting isn’t specifically intended to correct creasing or damage caused by poor storage conditions or bad handling but can also be an opportunity to improve something that otherwise might not display well at all.